Applications

Robots and Automation

Today, many repetitive or dangerous operations, especially where moving and manipulating objects is necessary, are delegated to robots. Their use in factories is constantly growing and this generally translates into an increase in efficiency, precision, safety and a reduction in production costs.

The robot is often inserted into production lines both to feed machines such as work centers and at the end of the line to stack/put away the pieces once produced. CNI numerical controls can move the most commonly used robots in the industry listed below:

Cartesians

in which the mechanical components reproduce movements that mirror a Cartesian axis system with up to 6 degrees of freedom.

Anthropomorphic

which reproduce the movements of a human arm; in joint or Cartesian mode with the addition of axes for “following” and “flying lock”

Collaborative

anthropomorphic robots capable of assisting humans in repetitive operations, with particular attention to safety, working in close contact with the operator

Robots are widespread in many industrial fields and are suitable for performing repetitive programmed movements, but what makes the big difference in applications today is their programming method. The simplest programming method is self-learning, but CNI has developed software that allows programming using the same CNC tools (ISO language, PLC Function Block, simplified HMI). Furthermore, thanks also to the integration of cameras, it is now possible to build a different work program for each piece, with decisions taken automatically and quickly that make their use much more flexible even in sectors where it was not thought possible to work alongside humans. Below are some applications developed by CNI Group in which robots are used. The simplest programming method is self-learning, but CNI has developed software that allows programming using the same CNC tools (ISO language, PLC Function Block, simplified HMI). Furthermore, thanks also to the integration of cameras, it is now possible to build a differentiated work program for each piece, with decisions taken automatically and quickly that make its use much more flexible even in sectors where it was not thought possible to work alongside humans.

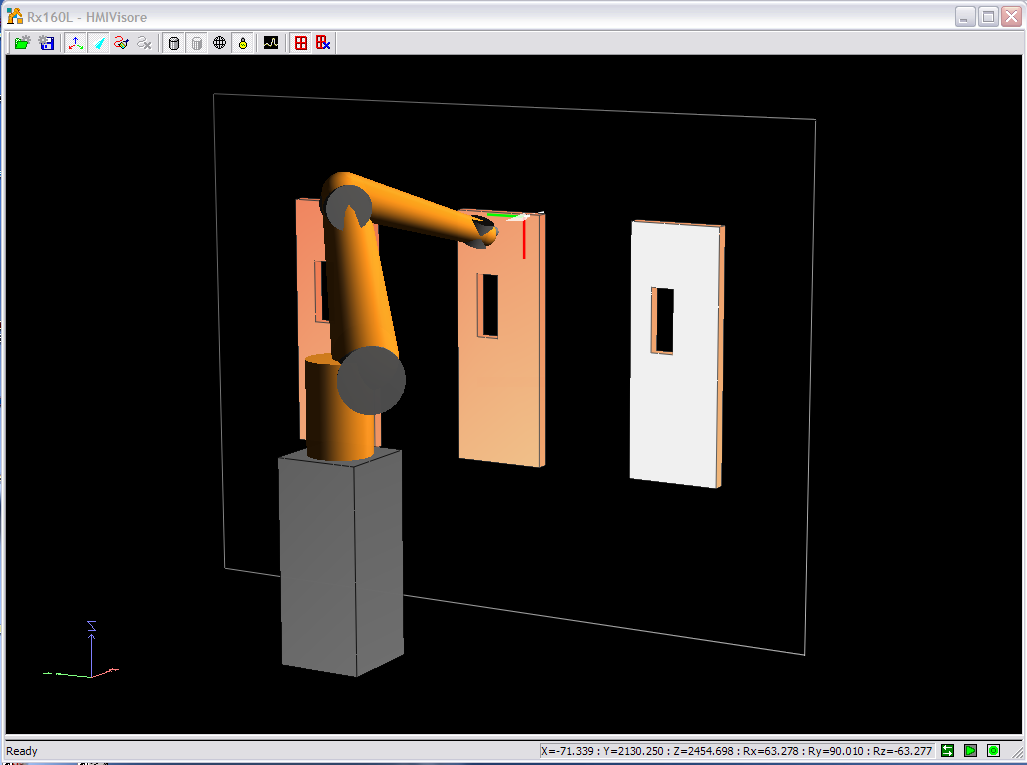

Painting

The wooden window frame is a product that is normally custom-built and was traditionally made by the carpenter with many manual operations. The automation of the carpentry shop, thanks also to the contribution of CNI numerical controls and computer systems, today allows the production of window frames on machine lines in a completely automatic way even when the pieces are different from each other. Painting is the completion of the production process and CNI has developed a software that, starting from the acquisition of the shape and dimensions of the window frame, builds a specific work program for the needs of each type of piece in compliance with the quality, finish and speed of execution, controlling the robot (Cartesian or anthropomorphic) through its own CNC; the software allows the management of the rotations of the piece for double-sided processing with master-slave robots, all without stopping the conveyors and managing the accessory functions (color change, head cleaning, etc.)

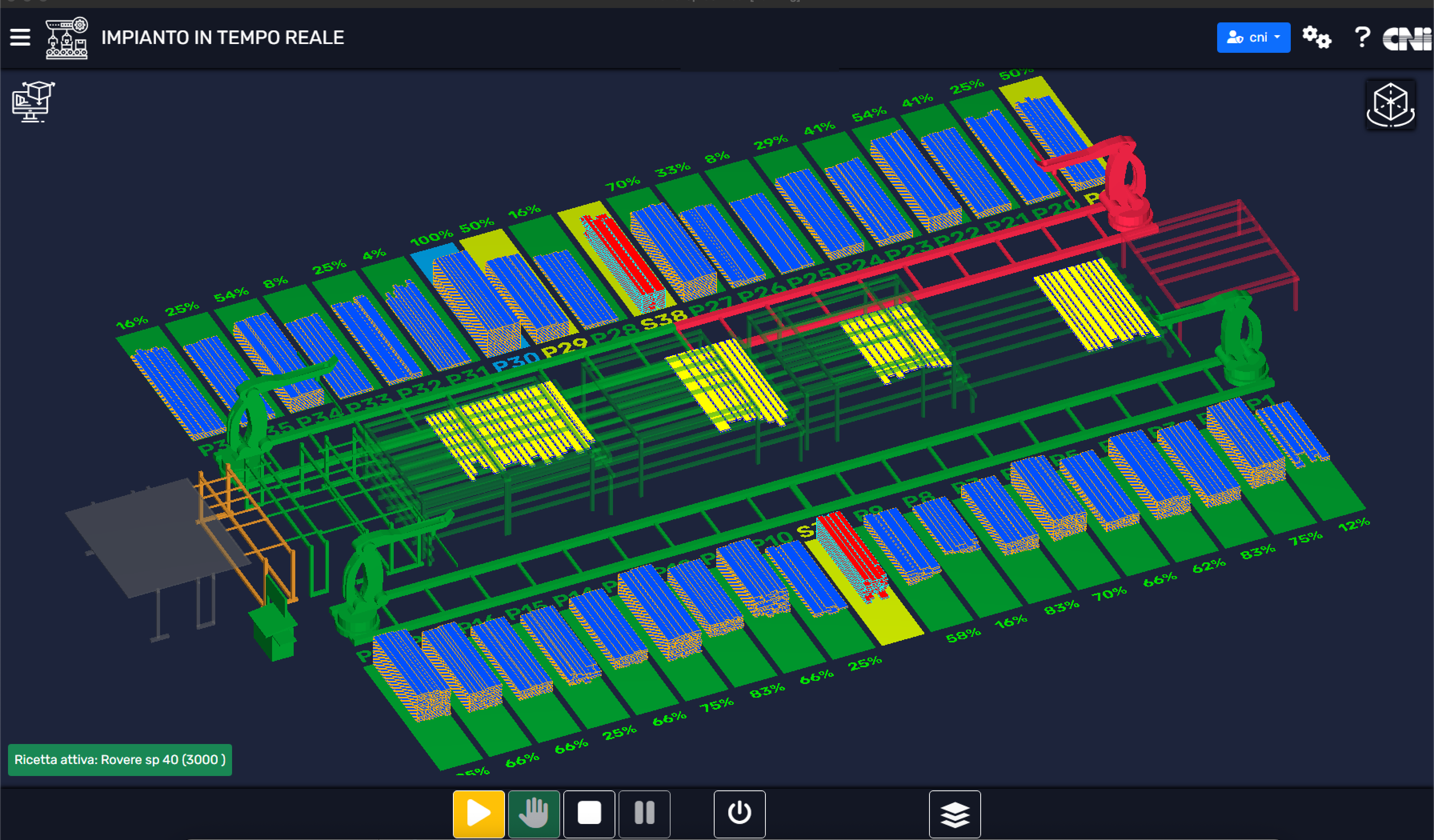

Automatic palletizing

CNI Group often finds itself having to manage anthropomorphic or Cartesian robots of different brands inserted in production lines for loading, depositing, and storing the pieces produced. In addition to controlling the robots for the movements to be performed, CNI optimizes and rationalizes their work. Often there are multiple robots that must work in synergy, coordinating with each other. Intelligence is transmitted to the robots through the supervision of the plant, to move them according to productivity logics, making them make choices dependent on the various cases encountered during production, reproducing the behavior of an operator.

Collaborative Robot

Collaborative robots are not used for very large movements or to move large masses, but to repeat operations similar to those performed by a human, even alongside them and respecting their safety. In fact, these robots can be easily blocked with a simple touch of the hand. In one of the CNI applications, the collaborative robot was used for a testing system designed to check toilet paper rolls, specifically the tearing of the paper flap. The robotic arm is commanded to take and tighten the paper flap, with a calibrated force all the tears present in a roll are repeatedly performed, thus verifying the correct processing of the paper. The check is visual and is performed via a camera. This operation was previously performed manually, but it was extremely wearing for the operator’s joints, causing serious damage after just a few days of work. In this case, the robot’s collaboration was highly appreciated.