Production automation solutions

IIoT Solutions

CNi is at the forefront of developing Industrial Internet of Things (IIoT) solutions. Our IIoT solutions are designed to connect industrial machinery and systems, collecting real-time data and transforming it into actionable insights to optimize production processes. With our experience and technological expertise, we offer customized solutions that improve operational visibility, predictive maintenance and overall efficiency.

iSentry

iSentry is an autonomous and non-invasive system applicable to systems and machines for data collection via integrated sensors. The collected data is processed and stored locally and made available to any device connected to the LAN (Android, IOS, Chrome, Windows, Linux, MacOS).

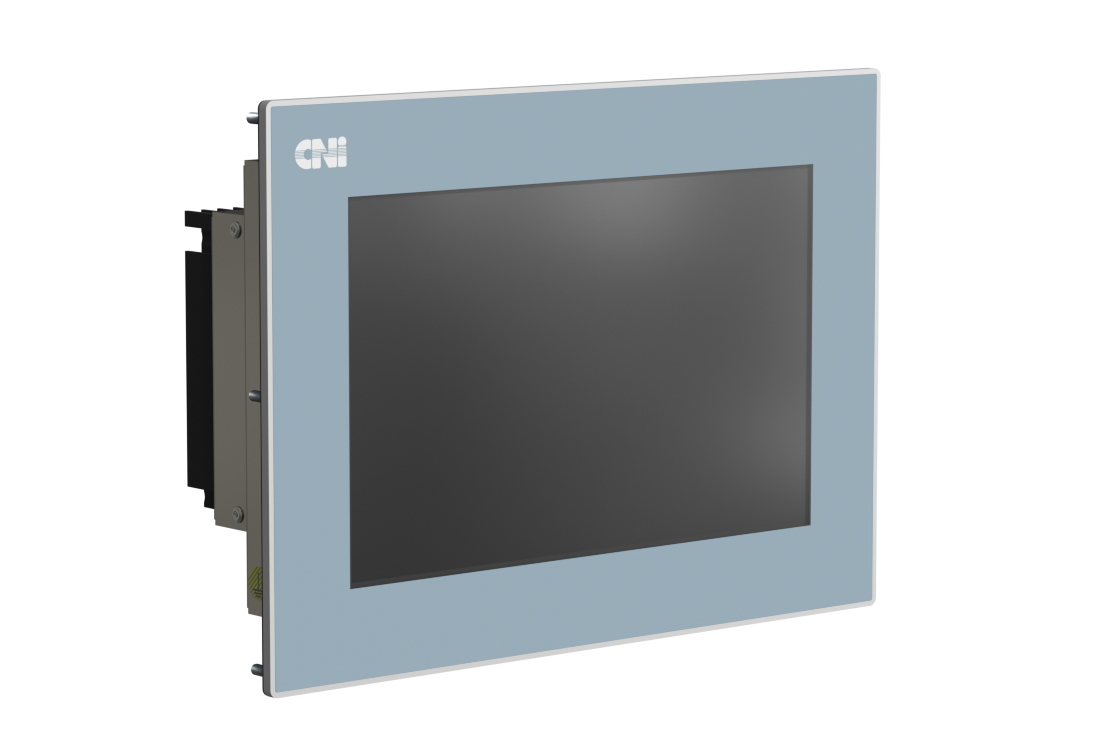

Machine Data Collector

The MDC (Machine Data Collector) system designed by CNI, installed on a work center, allows you to collect significant information from the machine and make it available on a database and in the office both to monitor productivity but also for diagnostics and maintenance. The information is collected mainly by the machine control unit (PLC or CNC) via proprietary communication protocols implemented on the MDC, but also via sensors, mounted where necessary on the work center, to detect other quantities useful for monitoring the operation and health of the machine. The system is made up of the CNI IPC410 Touch Screen industrial PC equipped with various network ports, to allow the connection of the machine CNC/PLC, to connect any devices and sensors and to connect the MDC to the company server.

Mini MES

MES (Manufacturing Execution System) software package in a lite version, developed according to Web technology, capable of bringing specific dashboards for collecting and sending data to the machine to different workstations in the office, in accordance with the Directives provided for Industry 4.0. It allows you to:

- Highlight the machine status graphically by collecting alarm and warning signals.

- Edit and management of the work list to schedule the programs to be executed on the machine, with collection of piece execution times.

- Machine production control and progress, with productivity graph.

- Collection of alarms, machine times (downtime and production), piece counters or specific ones for any maintenance interventions.