Business Unit

Vision systems

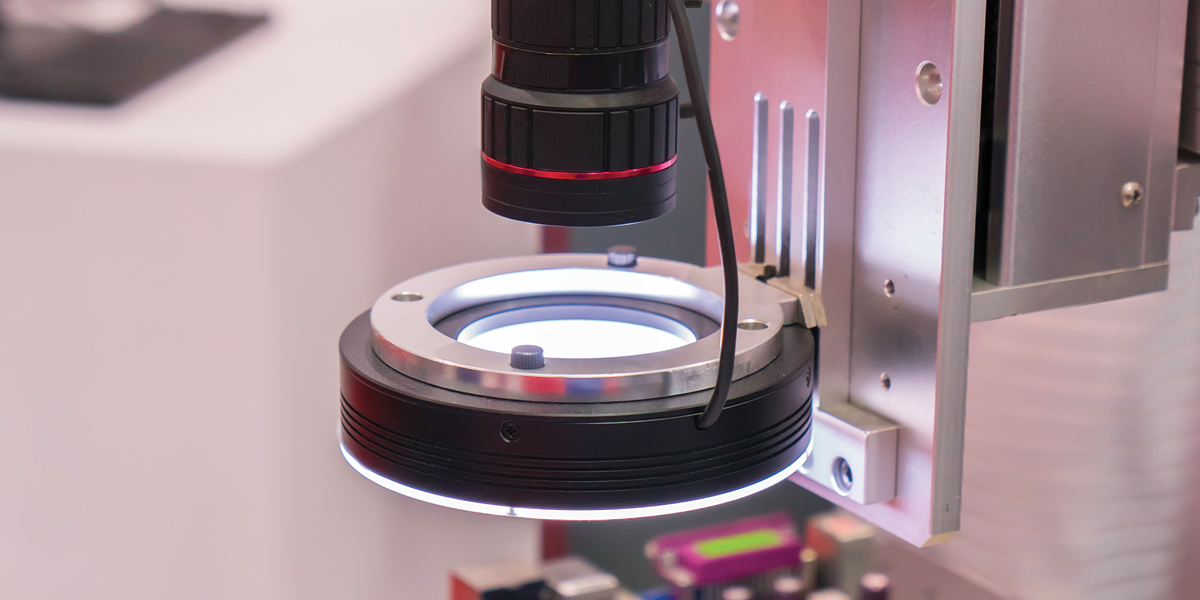

CNI Group creates custom vision systems for the industry, integrated into the production process of both the line and the machine.

It always works in close contact with the customer, starting from the analysis, then moving on to dedicated research and development, up to installation and assistance. Innovation and integration, our corporate values, allow us to offer solutions to complex and technologically advanced needs:

- Machine vision

- Interspectral imaging

- Custom R&D

The combination of skills and technologies allows us to go beyond traditional vision systems, controlling the invisible and the special. The complete integration with the machine and the process makes the added value of the solutions developed tangible and concrete. The development of ad hoc solutions for our partners has generated excellent results in numerous fields:

- Agri-food: in-line selection systems

- Wood Industry: Measurement and Quality Control Systems

Solutions

CNI inspection systems are applied in production, assembly and packaging lines, they allow to inspect up to 100% of the products even when moved at high speed. Among the main advantages of these systems we can list:

- do not place non-compliant products on the market, reducing the number of returns and assistance to your customers

- monitor quality progress in real time, providing immediate feedback to intervene on processes in the event of product quality drift

- return detailed information that can be used to increase production efficiency

- automate the quality control process, allowing resources to be dedicated to other higher value-added activities.

- Establish an objective and repetitive standard for quality control

- Do not alter the product as the test is non-invasive.

The basic features of the systems are:

- 2D/3D dimensional control

- Inspection check of the workmanship

- Defect identification and classification

An automatic selection system using artificial vision allows you to automate manual or mechanical selection systems with the help of innovative technologies, creating new processes capable of completely changing existing sectors.

Among the main advantages of these systems we can list:

- Automate manual sorting processes, increasing production capacity and reducing operating costs.

- Greater flexibility in the selection process by being able to adapt to changes in the product to be selected

- Obtain a reliable and repetitive selection according to configurable standards through completely customizable logics

- Control the selection process in every detail and flexibly from the selection and classification rules to the management of the automation system of the “unloading†of the selection product

- Obtain both production statistics and real-time data of the sorting process to quickly adjust the system to adapt to changes in product or demand.

The basic features of the systems are:

- Dimensional selection

- Weight selection

- Selection by color

- Selection for shape defects

- Selection for aesthetic surface defects

- Selection by volume

- Selection by internal material characteristics

Systems capable of measuring and verifying both in-line and offline the dimensions of objects and internal processes to establish compliance or non-compliance with reference measurements.

Among the main advantages of these systems we can list:

- Objectivity of the measurement: not dependent on interpretation

- Repeatability of the measurement value obtained over time.

- Speed ​​in performing measurements, which would be slower with other instruments.

- Non-contact measurement, without risking product alterations.

- Possibility to automate measurement procedures

- Feedback to operating machines based on the detected measurement.

- Production of documentation to certify the measurements taken.

The basic features of the systems are:

- Camera systems

- Structured light

- Measuring sensors

By leveraging the group’s expertise, we are able to provide and create solutions that are tightly integrated with automation, ensuring superior performance.

We are able to satisfy specific needs through dedicated research and development activities in collaboration with the customer. Customization involves close collaboration by sharing information for the realization of projects, which leads to establishing a partnership relationship.

Customized vision systems create innovation by being able to innovate the business where they are applied, inventing new products or applications, generating competitive advantages.

The creation of an inspection system involves several phases:

- Analysis of customer needs.

- Feasibility check using parts and samples to inspect.

- Verification of existing quality control procedures, proposing possible automation changes with new technologies.

- Define standards to be able to measure quality like other quantities, thus being able to verify the quality level of the products.

- Practical application of the studied solution.